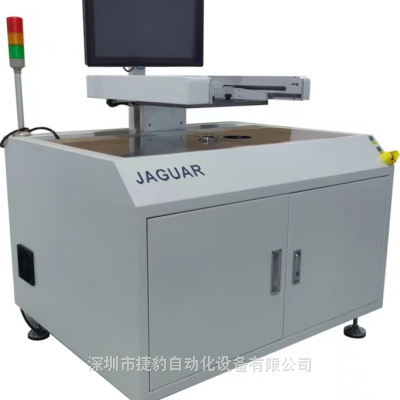

选择性波峰焊-JAGUAR-X6040是一款高精度***PCB板插件焊锡设备,专为PCBA线路板焊接设计,适用于多种复杂工艺。

高效快速识别、高精度焊接,提升生产效率,精准控制焊接区域,避免不必要的消耗。适应性强,兼容多种规格线路板,满足不同需求。智能化操作让您的焊接流程更高效可靠!

1、全功能性离线机型,占地空间紧凑.

All in one machine, in same XYZ motion table combine selective fluxing and soldering, compact & full function.

2、PCB板运动,喷雾与焊接平台固定。

PCB board movement, fluxer nozzle and solder pot fixed.

3、高焊接品质。 High quality soldering.

4、可置于生产线旁进行焊接工作,组线相当灵活。

Can used beside production line, flexible for production line forming.

5、全电脑控制,参数均在电脑上设定与保存。生成配置文件,便于追溯与保存。

Full PC control. All parameters can set in PC and saved to PCB menu, like moving path, solder temperature, flux type, solder type ,n2 temperature etc, best trace-ability and easy to get repeat soldering quality.

标准机器包括:

Standard machine include:

序号Serial | 名称 Item | 内容 content | 数 Quantity |

1 | 控制系统 Controlling system | 电脑一体机All-in-one computer | 1套(set)

|

控制器及转换卡 Controller and conversion card |

2 | 运动系统(PCB板运动) PCB Motion table | 三轴平台 xyz motion table | 1套(set)

|

XY轴全配步进电机及驱动器XY axis is fully equipped with stepping motor and driver |

XY轴全配同步带及滑轨XY axis is fully equipped with synchronous belt and slide rail |

Z轴全配滚珠丝杆Z-axis is fully equipped with ball screw |

Z轴全配伺服电机及伺服驱动器 Z-axis is fully equipped with servo motor and servo driver |

3 | 选择性喷雾系统 Fluxing system | 进口喷射阀Imported fluxing jetting valve | 1套(set)

|

助焊剂盒flux tank |

喷雾气控 flux pneumatic system |

4 | 选择性焊接锡炉 Soldering pot | 12KG锡炉,叶轮,流道,伺服系统12kg capacity solder pot, impeller, tunnel, servor motor | 1套(set)

|

焬炉温控系统 solder temperature controlling system |

氮气在线独立温控系统n2 inline heating system |

标配5个焊接喷嘴(内径 4mm x 3pcs, 5mm,6mm ) Standard equipped solder nozzle |

5 | 机器壳体 Machine chassis | 机架及表面喷粉 machine frame/cover & painting | 1套(set)

|

机器分项说明:

Machine explanation:

组成1:机器软件系统: Part1: Software

基于WINDOWS 10开发的软件功能,操作人性化与可追溯性良好。

All software system developed by base on Windows10 system, with good trace-ability.

可直接使用PCB图片进行路径编程,路径起始点,焊接移动速度,空行程速度,Z轴高度,波峰高度等均可在电脑上设定。

Use scanned picture as background for path programming, moving speed, dwell time, empty move speed, Z height , wave height etc all programmed for different solder site.

关键参数的软件完全监控,比如温度,速度,压力等等。 Critical parameters are totally under monitoring by PC software, like temperature, speed, pressure etc.

组成2:运动平台系统:Part2: motion system

轻量化的运动平台设计,提高运行速度的同时***平台的刚性。

Motion table was designed base on lighting concept.

伺服电机与步进电机提供运动动力,滚珠丝杆 同步带与直线导轨进行导向,定位***,噪音小,移动平稳。

Servo motor and stepping motor provide motion power, ball screw synchronous belt and linear guide rail guide, accurate positioning, low noise, and smooth movement

组成3:喷雾部份 Part 3: fluxing system

选用日本原产喷射阀,适应各种助焊剂

Japan original injection valve, adapt to various flux

助焊剂采用不锈钢盒贮存,***喷雾压力恒定,不受助焊剂多少的影响。

Flux is stocked by PP plastic pressure tank, make sure pressure stable without influenced of amount of flux.

组成4:选择性锡炉部份 Part 5: solder pot

锡炉温度,氮气温度,波峰高度等均可电脑设定.锡炉温度,氮气温度,波峰高度等均可电脑设定.

Tin furnace temperature, nitrogen temperature, wave height, etc. can be set by computer

锡炉内胆为钛合金不锈钢,绝无渗漏。外置式发热板,热传递均匀。

The tin furnace liner is made of titanium alloy stainless steel without leakage. External heating plate, uniform heat transfer

氮气在线加热装置,***锡炉良好的润湿性以及减少氧化物产生。

N2 online heating system, to wet the soldering perfectly and reduce the solder dross.

组成5:PCB放板机构:

人工放板与取板。

Load board manually and unload board manually

组成6:机器壳体:

整机钢结构,底部加基板以增加机器稳定性,减少震动。

Metal welding structure, with thick metal plate as base, so to reduce vibration and make machine more stable.

更多设备参数细节,欢迎致电详谈!